whatever you do in life, do it with all your heart..

that’s what we have been doing right from the start

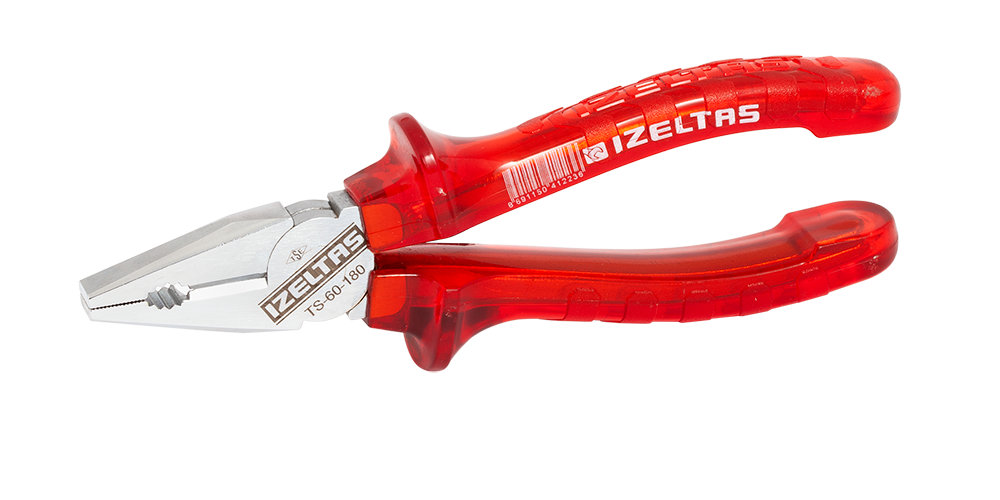

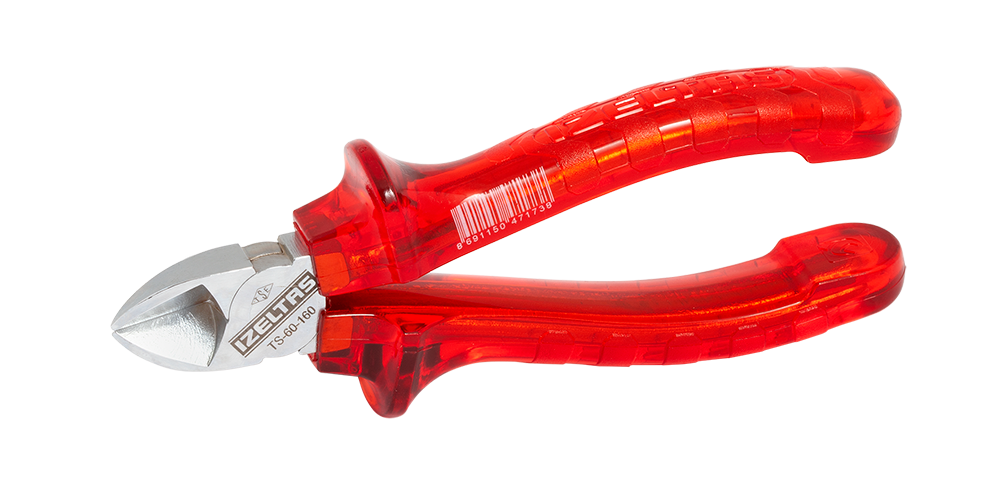

PIPE WRENCHES AND PLIERS

The process of developing a product starts with the creation of 2D drawings and 3D models of the mold and device surfaces in ergonomic use proportions that adhere to applicable standards. Analyses are conducted on molds / products using the superforge forging simulation program and the Ansys workbench strength analysis program. CNC machines, milling machines, and grinding machines are used to accurately process molds and associated equipment in preparation for the production process.

The manufacturing process starts with the cutting of various sizes for each product using template presses and saws. The cut templates are heated to roughly 1100 degrees Celsius in ovens and are then ready for forging. Hydraulic and drop hammer forging machines are used to form it. After being cleaned of any remaining burrs, the products are prepared for processing. Automation of the machining processes begins with robots on CNC machining benches. Broaching and grinding benches are used to shape the products before they are delivered to the assembly line and then to the heat treatment department for hardness. Chrome plating is applied at the Coating facility to increase corrosion resistance and product life, while painting using powder paint is applied in the Painting facility. After the plastic handles are installed, the products are transferred to the marking department to be included to the Izeltaş family by laser and pad marking. Our products, which are approved for quality control one by one, are packaged in their own unique boxes at our packaging department and prepared for distribution.